In one article we discussed the choice between LFP (or LiFePO4) batteries and lead acid batteries. In a second article, the business case, we saw that LFP batteries are cheaper. So, we installed a 42.5 kWh LFP battery bank, to serve our household and electric engines of our self-sufficient ‘Ya’.

How did it work out? Much differences with the old lead acid batteries are caused by the lower internal resistance in LiFePO4 batteries. This is great for the efficiency, and it has other consequences. We work them out, and others.

You get what you see

The lead acid batteries always have a loss on taking the energy in and delivering it out again. This makes you a bit uncertain/unsure how much energy you actually have. To prevent this loss, we tried to use the energy immediately when it is produced (by solar, wind or hydro). So we baked our bread around noon, and made our dinner before 5 PM. It saved 10-30%. Technically, the high internal resistance is the cause of this (see the first article).

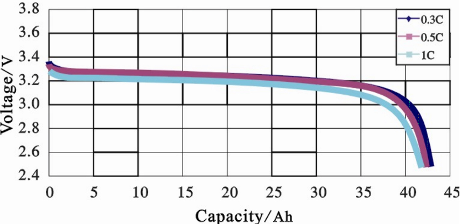

The LFP hardly has this disadvantage: the energy coming into the LFP batteries, will be the energy coming out. What you see going in, you also get it out. It makes you happy.

You get what you want

Now our engines work better and more reliable in the extreme power range. When the lead acid battery bank was low, I have always doubted if the electric engines could deliver the full 15 kW power they should be able to. Well, they couldn’t, because the voltage dropped too much. Once when the (old) lead acid battery bank was low, and I blew both the engines full power for 5 minutes, the engines stopped. The engine displays said “voltage too low’. It could not deliver the 15-kW needed.

You will see the same if you have a heavy power equipment, like an anchor winch, connected to a 30-40% charged lead acid battery.

By contrast, the LFP delivers the power you want till the battery is really empty – or at least to 10%.

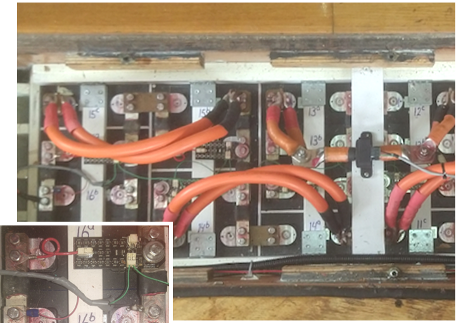

Check your cables and connections

You replaced the batteries from lead acid to LFP? Then switch everything on full power and check if your cables and connections don’t get hot-it can cause fire! This can happen now since, due to the internal resistance, the old lead acid batteries never delivered the power that was asked for. But the LFP’s really do deliver this power! So now you get more current through the cables and connections. These cables and connections have resistance, so that means more heat. When a cable is hot (or a connection is bad), you will feel heat there. Prevent fire and fix the connection or replace the cable for a thicker one.

LFP is all-automatic

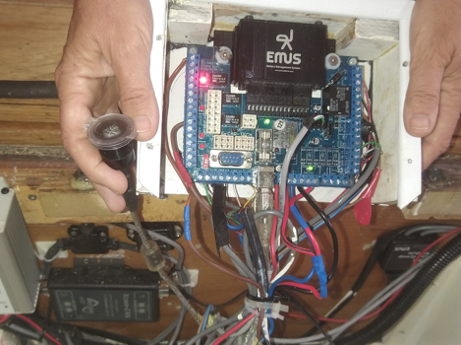

With the LFP-batteries you get a complete Battery Management System (BMS). Initially you (or your supplier/installer) plugs in a computer on a USB connection to configure all settings. Once set, the system runs.

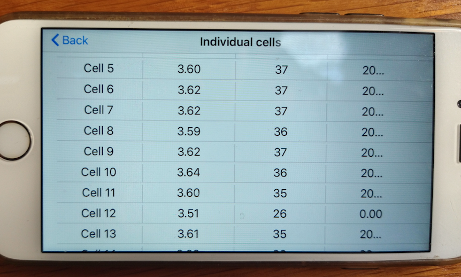

There is a display with the BMS, for the daily use and readings. But you can also connect your cell phone through blue tooth (see above: ‘You get what you see’). It shows you everything, even the status of each cell. This display is for the daily user.

All-automatic commits to know your system

Most accidents on yachts happen, because we leisure skippers simply don’t know how the equipment is working. It is nice to live not hindered by any knowledge. But once it will go wrong, also with an excellent working ship and equipment.

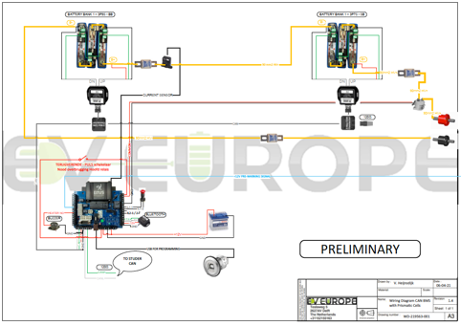

OK, we are leisure sailors, but there is a limit to not knowing what you are playing with. I would say, the minimum is that you can draw out the equipment of your system and can find it on board. This is:

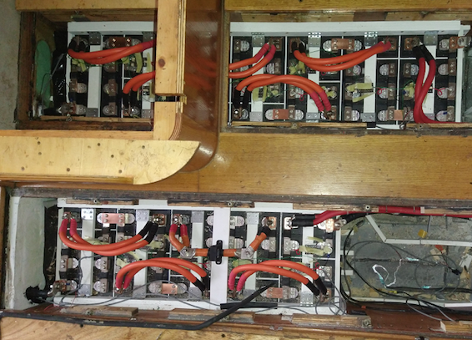

- The battery cells

- The BMS with:

- The (12 Volt) feed wire to the BMS

- The fuse of the feed wire

- Contactor (the central big relay switch)

- Emergency button (switch)

- The cable to connect the BMS to your computer

- The cable or Bluetooth connection to your display

- Display with the basic numbers (Volts, Temp, Watts coming in or out)

- Display with the numbers per cell

- (If installed: Low/high voltage warning beeps)

- The CAM (‘talking device’ between BMS and charger)

- The charger and the AC (110/220 V) plug

- The AC fuse of your charger

LFP is zip maintenance

Over the years, I developed a relationship with my lead acid battery bank. Next to some attention, the bank needed maintenance. For lead acid batteries, this means: keep your lead acid always full. But I could not do that. The bank became ‘lazy’. So, every three months I made some deep charges and discharges, I measured the density of the acid mix, and topped up the evaporated demin water.

LFP comes with a BMS and it does not need this TLC. The BMS saves you from trouble and does the maintenance. This consists mainly of balancing the cell voltages, which means: keep them equal. This is done automatically during the last charging phase, nearing the 100%.

On ‘Ya’, we live and sail fossil free. Our battery bank is our energy buffer and never at 100%. So, the supplier advised us to do a full charge every 3 months. So, our maintenance consists of putting the 220 Volt plug of the charger in the shore power for a day every three months. We can handle that.

In the next and last article all extra features will be treated on a more technical level. We will discuss things like:

- The alternator. With the lead acid battery bank, one never can switch the main switch off when the alternator runs (like a windturbine). This would blow the alternator. With the LFP bank this switch is automized. Reason to tackle this problem.

- The feed of the BMS and contactor can become a Catch 22. We discuss that.

And we discuss all other extra features and possible problems we found in the installation.

Want to know where we are? See

https://fossilfreearoundtheworld.org/map-where-we-are-now-position-of-the-ya/

Want to subscribe to this newsletter? See https://fossilfreearoundtheworld.org/blog/