Something a bit more this week, for skippers only I am afraid. And only two pictures (but one of them is artistic!).

As soon as a sailing yacht sails, it speeds up. The propeller in the water starts to turn. This rotation can drive a dynamo and thus generate electricity. Just as a windmill needs a little wind to deliver, the propeller only turns through the water at some speed. That’s a law of physics. At about five knots, the propeller usually turns hard enough to provide electricity.

Here is the description of whether it will fit on board your sailing yacht at all. (But there will not follow a technical description how to install it.)

Hydrogeneration works well with a fixed propeller, but it works better with a variable propeller. The propeller must be of some size. Small propellers require higher speeds.

It is striking that the rotation of the propeller on most courses has little decelerating effect on the speed of the boat. For example, at a speed of 5 knots, the loss of speed is no more than a quarter of a knot. There is a clear loss only on upwind rates. On that course, all the forward energy is needed to gain speed. With the hydrogeneration in operation, the ship becomes visibly more glued. If additional power is necessary via hydrogeneration, it is better to drop 10 or 20 degrees on that course.

In practice

In practice, hydrogeneration can already yield 50 to 100 watts from a boat speed of five knots. It depends first and foremost on the prop and then on the technology behind it. 50 to 100 watts may not seem like much, but when underway on the high seas the system works 24 hours a day and 50 to 100 watts for 24 hours is sufficient to provide an energy-efficient ship’s household with energy.

With a score of 100 watts, hydrodynamics already generates 2.4 kilowatt hours per day, which is more than solar and wind energy combined on most ships. If the boat speed increases, the efficiency becomes even higher. Hydrogeneration on fast catamarans yields ten or twenty times that.

Why

The huge advantage of hydrogeneration is security, reliability. Long-distance sailors are often concerned about whether they will arrive at their destination with enough energy. With the use of hydrogeneration, the reverse often happens: the battery bank is full on arrival.

The propeller shaft alternator; the oldest form.

Long before solar panels or wind turbines were used on board, sailing skippers already used the propeller shaft dynamo. That was a very welcome additional energy supply because of the energy-consuming lamps and the relatively expensive batteries. Surprisingly, this system is hardly found on board anymore.

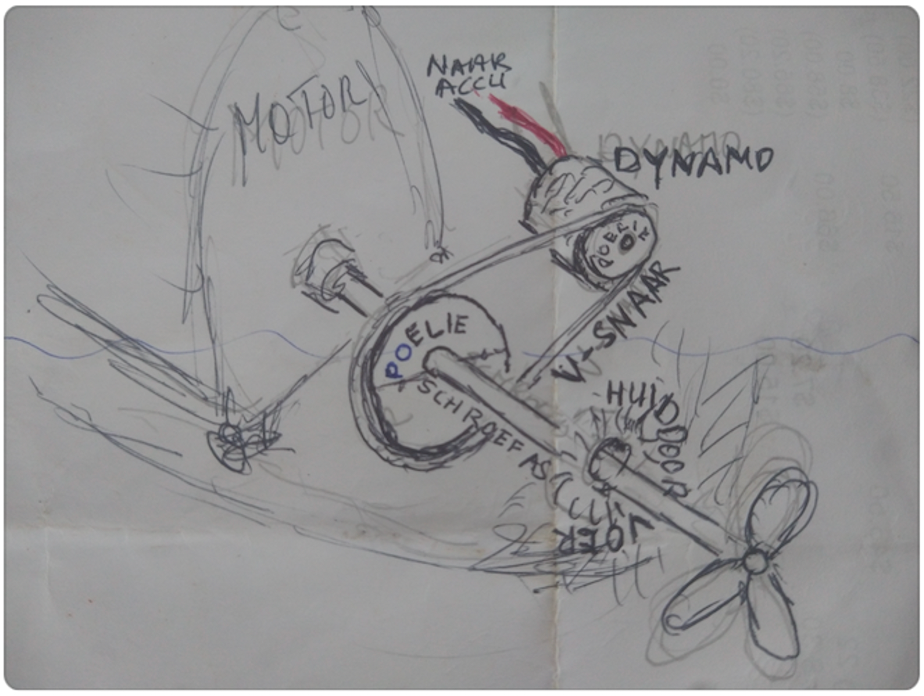

The operation of the propeller shaft dynamo is simple: when the propeller starts to turn under sail, it drives the dynamo via a pulley and a V-belt, which supplies electricity to the battery.

This is a schematic picture of a propeller shaft alternator. A dynamo is mounted next to the propeller shaft. There is a small pulley on it. A large pulley is mounted on the propeller shaft. When the propeller starts turning, the large pulley also turns and drives the small pulley on the alternator via the V-belt. The alternator therefore rotates and supplies the current to the battery.

The propeller shaft alternator is a cheaper supplier of electricity than the hydro generator from the shop, even if you have it installed.

Align propeller and alternator

When using a propeller shaft dynamo, the propeller and dynamo must be properly matched. Because when the propeller turns, the dynamo also has to turn fast enough to supply power. The speed of the propeller and alternator is matched with the size of the pulley on the propeller shaft. So there must be space around the propeller shaft to mount such a pulley. You can easily calculate how much space that requires. The starting point for the calculation is that the propeller rotates stably at a sailing speed of 5 knots.

Alternator speed

The speed of an alternator is easy to determine, because it is stated on the specifications. An ordinary car alternator usually delivers well at 1000 RPM (Rotations Per Minute). That’s what we assume here.

What is the propeller speed?

You can determine how many revolutions the propeller makes in three ways. The first and simplest is to measure the RPM with a tachometer gauge, an expensive thing that nobody has.

Sound app

The second is by using a sound app on your smartphone. Place a piece of tape on the propeller shaft with a piece of tape sticking out. Place a plank next to it and every time the protruding tape passes it, you will hear TICK. Record this on a phone for exactly one minute. If you play it in slow motion or enlarge the visual representation, you can count the taps. That is the number of revolutions per minute.

Math

The third way is math. Let’s say you have a 14″ X 15″ propeller. The diameter is then 14 inches. The pitch is 15 inches. When the tip of the propeller has made one revolution through the water, it has theoretically traveled 15 inches. How many revolutions per minute is that at 5 knots?

5 knots, that is 5 X 1852 meters = 9260 m/hour.

RPM goes in rotations per minute, so that would be 9620 : 60 = 154 meters/minute.

In inches/minute that is 154 X 39.37 = 6076 inches/minute

To get into the RPM, we need to divide the distance through the pitch: 6076/14 =380 rpm. This is the theory. The propeller with a pitch of 15 inches appears to cover much less distance after one revolution. A propeller does not turn through water like a wood screw through wood. Water is flexible, so it has less grip on the propeller. This phenomenon is called slip. When the propeller is driven through the water, such as when loading, there is so much slip that the propeller runs at two-thirds of its theoretical speed. So: 2/3 X 380 = 253RPM. The propeller turns at 5 knots, so 253 RPM, and the alternator must turn at 1000 RPM. The ratio between the alternator pulley and the propeller shaft must then be 253 : 1000. That is 1:4. If the alternator pulley has a diameter of 5 cm, the propeller shaft pulley must be 20 cm. If that diameter fits around the propeller shaft, then the propeller shaft generator can be installed and it now only concerns the technical implementation.