Too technical? Then go to the end of the article. There you find a picture with a cute model (says Inge) trying out the shower!

The heating panel collects the heat and gives it to a cooling fluid. The fluid circulates through (or around) the boiler and gives the heat to the colder water. But that is just one function. The beauty of this system is that it is a multipurpose system: for heating and cooling. In this film you see a short description.

If you want to know more, check the drawings and the text here below.

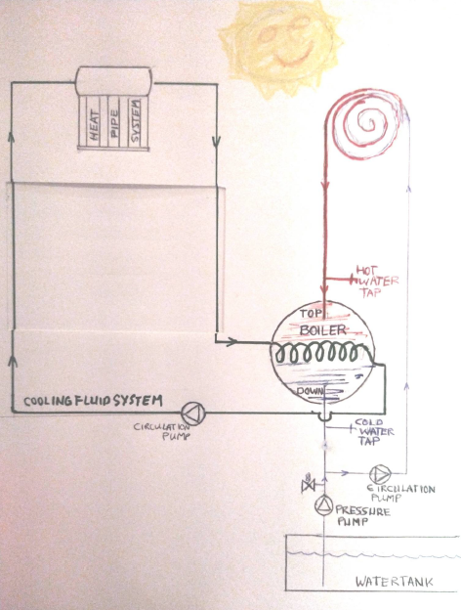

The Heat pipe in a basic system

This closed circulation system is filled with cooling fluid. The circulation pump makes the circulation. The fluid goes through the heat pipe panel. Only a first sunray through a cloud will heat up the water there.

The fluid then runs to the boiler, where it goes throught the boiler spiral , so that it heats the water in the boiler.

Then it runs back to the panel.

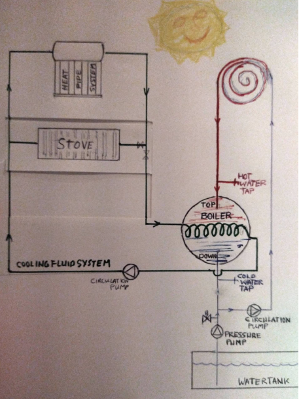

To a multi-purpose system

You can put a stove in the form of a radiator on board. It works sufficient in autumn; it will not give much heat.

There is a valve before it in the circulation system and you can choose if you want to let the fluid go through the radiator. If the valve is closed, it runs further.

You could for example use this stove in the evening, using the heat from the boiler. With an extra valve you close the heat pipe panel out of the system so you let the circulation go from the boiler to the stove and back.

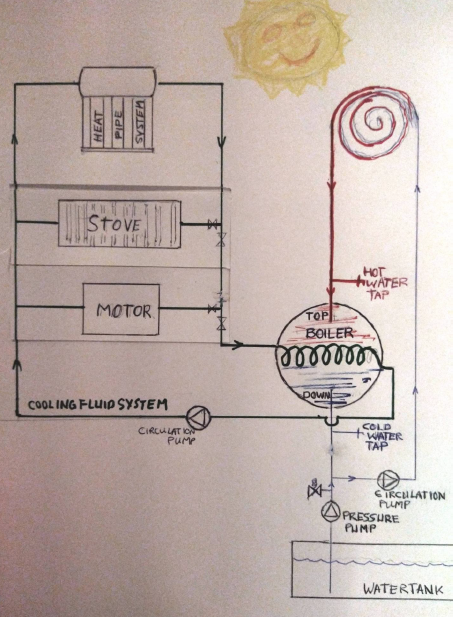

And you can do more. Here we show it on video:

You connect the circulation system of your motor into the circulation system. So, the motor is also a heater. An electromotor is highly efficient, so you won’t get much heat of it, but it works more efficient if it stays cool.

Especially for combustion motors it is interesting to build its cooling system into your cooling system. Combustion engines are terribly inefficient and the mostly produce more heat than propulsion. A diesel engine converts about 50% of the diesel into heat.

And on the other hand, your system can warm the motor up. A cold running combustion engine wears the engine out, so why not first heat it up? It saves your engine from wearing out.

Regulating the system

To get a high heat intake from your heat pipe panel, the circulation pump should run slow. That is the main thing to regulate. You can put a by-pass in it with a valve to lower the flow. Or if you like it the electrical way, put a resistor in your feed to lower the power to the pump. There are also electrical regulators with a pot meter.

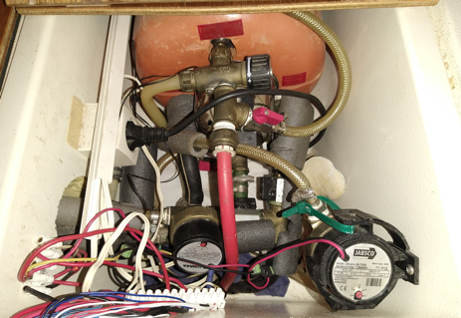

Put many valves in the system, so that you can do whatever you want, such as:

- Heat your boiler with the heat pipe panel

- Make your stove/radiator work with the heat of the boiler

- Cool your (electric) engine and controller, or your combustion engine

- Heat your boiler and/or your stove with your engine.

When you want to heat in the night, put a valve before the heat pipe panel, to prevent loosing heat there.

Simply use valves that you can open and close by hand. Just make sure that there is a flow in the system, because the circulation pump must be able to do its work.

Often, you see three-way valves in such systems. These valves always give way to or one way, or the other way. Disadvantage is that you must choose. You swith or/or, and sometimes you want and/and. For example if you want the radiator to be warm and the boiler, donot use a three way valve, but put just regular valves in, as drawn. Advamtage is that you can even regulate how much you want to feed to e.g., the radiator, and to the boiler. Or, when the motor produces heat, you open that valve.

First do it manually, and when you are experienced, you automize the options you want. You could put sensors everywhere in the system and connect them with valves. But that could make it much more complex than you want. Start with the basics first.

The test

With this heat pipe added, you can get really hot water and not only during summer. The spiral heater is doing great, and you can build it yourself. But the heat pipe panel is directly handy to build in. and it looks like it can take more heat out of the sun. Great to get a big hot shower, even in winter time.

You want to know more? Email info@fossilfreearoundtheworld.org